Winemaking: The basics

In South Africa Harvest is in full swing and soon all the cellars will be bursting at the seams with this year's fermenting grape juice. It is such a magical and stressful time of the year and I've heard that it's one of those things you wish could be over, but you can't wait for the next one to come.

Through my studies and chatting to a couple of winemakers I have been fortunate enough to learn about the processes involved in the cellar and what steps need to be followed to turn a tiny, juicy grape into the delicious liquid we sip on.

If you're keen to know a bit more about what is involved in making still wines, read on!

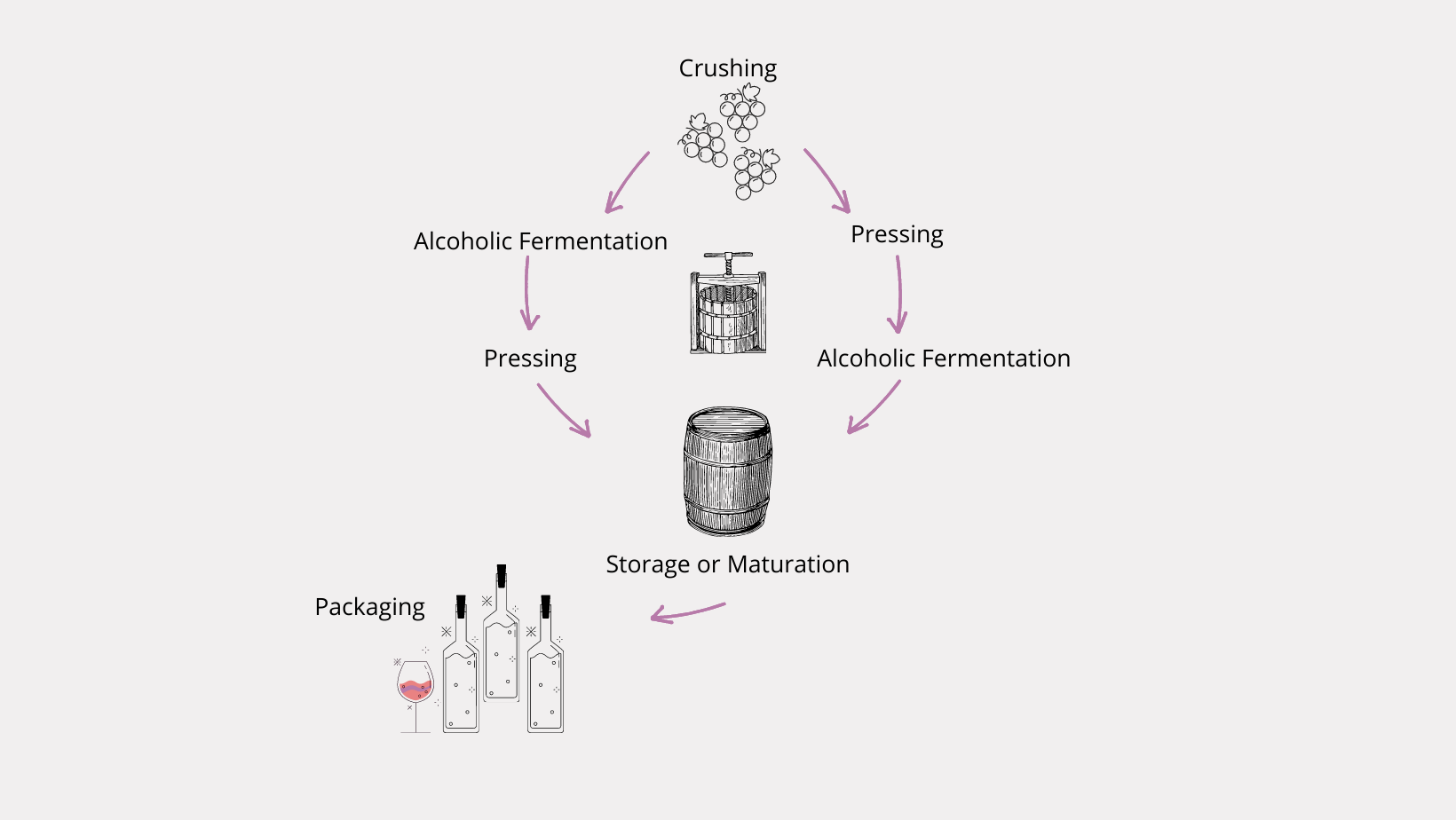

5 Steps to success

Step 1

The first step in making wine is harvesting grapes at their optimal ripeness levels and transporting them to a cellar where the magic begins.

Grapes can be harvested by hand, which is very labour intensive, or by large machine harvesters that shake the grapes from the vines. Transporting the grapes from the vineyard to the cellar is a delicate process and care has to be taken for grapes not to become too hot or be crushed (among other things that can go wrong).

Once the grapes arrive at the cellar, which can be on the same farm or even a long distance away, the grapes are sorted, destemmed (if required) and lightly crushed to break the skins and release some of the juice, before moving to the next step in the process.

Step 2

This is where the red and white wine processes diverge somewhat.

Red and Rosé wine

For red and rosé wine grapes, the second step in the process is alcoholic fermentation. This involves yeast that is added to a large vat to allow the sugars to be turned into alcohol.

Juice that is destined to become red wine will spend a couple of days fermenting in contact with the grape skins. This contact allows the extraction of pigment from the skins, which is where the wine gets its colour from. Depending on the colour that the winemaker wants to achieve, the skins will stay in the vat until the fermentation process stops - this happens when all of the sugars are converted to alcohol by the yeast. Once the desired colour has been achieved, the wine is drained off the skins and moves to the next step in the process.

For rosé wines, the same process is followed, but the juice is left in contact for only a couple of hours before it is drained off the skins and the alcoholic fermentation continues without skin contact.

White wine

The second step for white wine is called pressing. This process involves the crushed grapes being put into a large machine called a press, that presses down on the grapes to squeeze out as much of the juice as possible. The pressed juice is then transferred to a fermentation tank for the next step.

Step 3

Red wine

Since the alcoholic fermentation is complete, but the fermented juice is still in contact with the skins, it is now time for the red wine to move on to the press to extract the juice.

White and rosé wine

At this time, the juice has been pressed and skins have been removed, but we still have only sweet grape juice. This is where the white wine enters the alcoholic fermentation phase and rosé wines continue the phase until all the sugars have been converted to alcohol.

Step 4

In this step the wines all catch up and follow the same process from hereon.

After pressing and alcoholic fermentation, the wines are transferred to inert (stainless steel or concrete) vessels or oak barrels or vats for storage and maturation. All wine is stored for a period of time before bottling. The time spent in the storage vessels as well as the type of vessel has an influence on the flavours that develop (or don't) during this time. Wines that are meant to be drunk early will probably spent only a couple of months in inert vessels, whereas wines that are meant for ageing will spend more time in, often, oak barrels. Longer time spent in storage is commonly referred to as maturation.

Once the desired flavours have developed and the winemaker is ready, the wines are moved into the next step.

Step 5

The next step in the process is bottling or packaging.

Most wines are put into glass bottles to be sold, but other options are cans, plastic bottles or bricks and also bag-in-box packaging.

Now, once the wines are in a more manageable container, they are shipped to resellers ready to be put onto shelves or into courier vans where we can get our hands on them.

I hope that you have found this interesting. Let me know in the comments if you would like to see more (or less) of these types of articles. Also, if you would like to receive these articles in your inbox, click on the subscribe button and send me your email address.

Follow The Wine Dream on Instagram and Facebook for more photos and tasting notes. 🍷